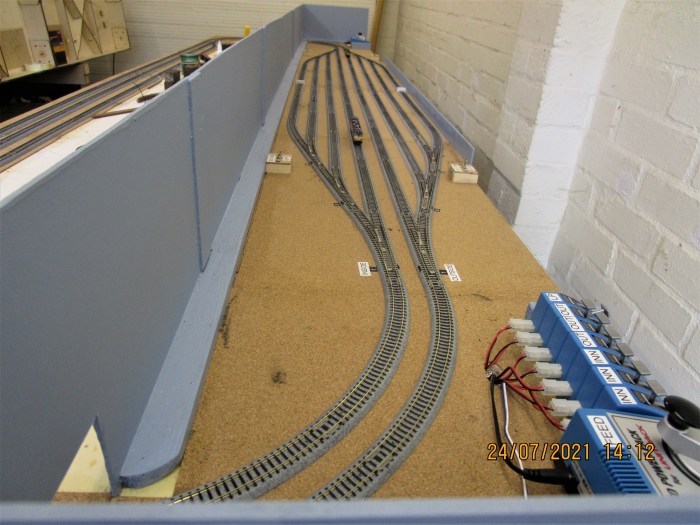

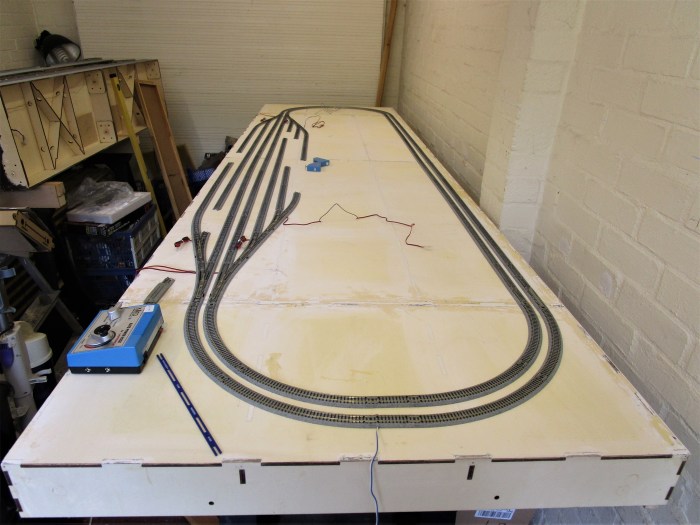

I am posting every move I make with the Kato track as it may be useful to others. Today I am preparing the track on the scenic sections for ballasting or should it be ballasting between the tracks and on the edges. I have purchased two packets of compatible Kato ballast to use, but at £7 a pack for such a small amount I decided to put a further layer of cork in all places that will be ballasted later to save on the amount of ballast needed. The below photographs show how I cut the cork to size, glued it and temporarily pinned it down, the pins are Peco and all are salvageable.

I intend to do a small section to see what is the best way to glue the Kato ballast down. I will use sandpaper to make a chamfer on all the cork on the edge of the track, this should help the finished appearance. You will note that I have started to disguise the wiring for the board joins.